Filter by

Clear filters

Apr 09th 2024

Exosens Adds Innovative Photon Counting System, LINCam

Feb 06th 2024

Occar renew their trust in Photonis' expertise

Photonis shall deliver 40,000 image intensifier tubes to boost military night vision in Germany and Belgium

KINTEX Exhibition Center Ⅱ.

FROM Sep 25th 2024 TO Sep 28th 2024

DX KOREA 2024

Visit Exosens at DX KOREA 2024 from September 25 to 28 in KINTEX Exhibition Center Ⅱ, Korea

Shanghai New International Expo Centre.

FROM Jul 08th 2024 TO Jul 10th 2024

Vision China 2024

Visit Exosens at Vision China 2024 from July 8 to 10 in Shanghai New International Expo Centre, China

Paris Nord Villepinte exhibition centre.

FROM Jun 17th 2024 TO Jun 21st 2024

Eurosatory 2024

Visit Exosens at Eurosatory 2024 from June 17 to 21 in Paris Nord Villepinte exhibition centre, France

Berlin.

FROM Jun 05th 2024 TO Jun 09th 2024

ILA Berlin 2024

Visit Exosens at ILA Berlin 2024 from June 5 to 9 in Berlin, Germany.

Anaheim Convention Center, Anaheim, California.

FROM Jun 02nd 2024 TO Jun 06th 2024

ASMS 2024

Visit Exosens at ASMS 2024 from 2 to 6 June 2024 at the Anaheim Convention Center, Anaheim, California, USA.

National Harbor, Maryland.

FROM Apr 21st 2024 TO Apr 25th 2024

SPIE Defense & Commercial Sensing 2024

Visit Exosens at SPIE Defense & Commercial Sensing 2024 from 9 to 12 April 2024 in National Harbor, Maryland, USA.

Munich.

FROM Mar 09th 2024 TO Apr 12th 2024

Analytica 2024

Visit Exosens at Analytica 2024 from 9 to 12 April 2024 in Munich, Germany

Jan 18th 2024

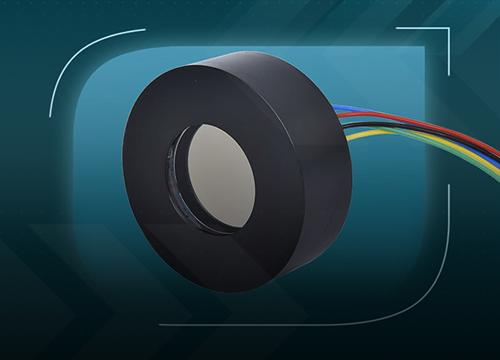

New Cutting-Edge 25 mm Image Intensifier

Exosens is proud to announce the expansion of its Photonis Ultimate Detection Scientific Imaging product portfolio with the introduction of the 25 mm Image Intensifier solution.

Nuremberg Exhibition Center, Germany.

FROM Feb 26th 2024 TO Feb 28th 2024

Enforce Tac 2024

Visit Exosens at Enforce Tac 2024 from 26 to 28 February 2024 at Nuremberg, Germany

Saudi Arabia.

FROM Feb 04th 2024 TO Feb 08th 2024

World Defense Show 2024

Visit Photonis at World Defense Show 2024 from 4 to 8 February 2024 in Saudi Arabia

San Francisco, California, United States.

FROM Jan 27th 2024 TO Feb 01st 2024

Photonics West Booth 3273 - BiOS Booth 8273

Visit Exosens at Photonics West Booth 3273 - BiOS Booth 8273 from 27 January to 1 February 2024 in San Francisco, California, United States

Bordeaux - France.

FROM Jan 23rd 2024 TO Jan 25th 2024

OPTRO 2024

Visit Exosens at OPTRO 2024 from 23 to 25 January in Bordeaux, France

Nov 29th 2023

Exosens signs partnership with Scientific Imaging Inc.

Exosens signs partnership with Scientific Imaging Inc. to distribute its wide range of high-performance cameras

Nov 24th 2023

Photonis, part of Exosens, Aids in TerraPower’s Mission

Photonis, part of Exosens, Aids in TerraPower’s Mission of Low-Cost and Carbon-Free Energy Solutions with Key Components of Operation

Nov 21st 2023

Exosens announces its CSR strategy

Exosens announces its CSR strategy to address current societal and environmental issues and employee expectations